Our Cutting-Edge Research Facilities

-

Southeast University, China

Southeast University (SEU) is renowned for its state-of-the-art experimental facilities that serve as a cornerstone for transformative research. These facilities, equipped with the latest instruments and technologies, play a significant role in fostering the ambitious projects of the IRI joint center, making it a hub for innovation and exploration in the heart of China.

-

University of Leeds, UK

Nestled in the historic city of Leeds, the University of Leeds stands as a beacon of research excellence. Their comprehensive and modern facilities, which have seen numerous breakthroughs, not only enhance the academic community but also provide robust support to the IRI joint center. Here, research transcends traditional boundaries, setting new paradigms for scientific inquiry.

Some of our Facilities at SEU

-

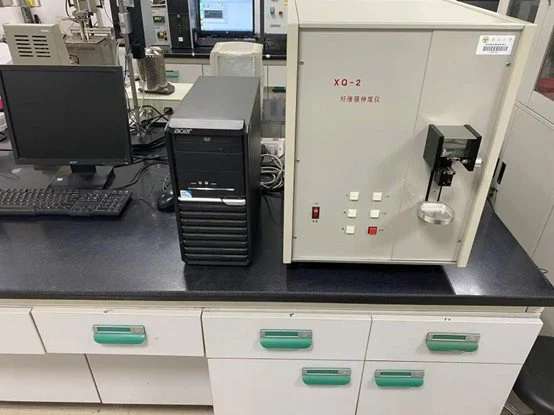

Multifunctional fiber strength meter

Index:

Measuring range: 0~ 100 CN;

Measuring error: ≤±1%;

Measurement resolution: 0.01cN;

Elongation measuring range: 100mm;

Elongation measurement error: ≤0.05mm;

Elongation measurement resolution: 0.1%

Function:

It can carry out fiber constant elongation elasticity, cyclic constant elongation elasticity, cyclic constant load elasticity, relaxation, creep and other tests.

-

Vibrating fiber fineness meter

Index:

Linear density measurement range: 0.6-40dtex;

Linear density measurement error: ≤±2%;

Clamping length: 20mm;

Pre-tension clamping accuracy: ≤±0.5%;

Resonant frequency measurement error: ≤±0.5%;

Function:

Single value, average value and coefficient of variation of linear density can be directly displayed

-

Conductivity tester for molten glass

Index:

Rated operating temperature: 1600 °C

(programmed temperature control);

Function:

The high temperature conductivity of glass

-

Marvin laser particle size analyzer

Index:

Measurement range: 0.02~2000 microns

Measurement principle: Mie scattering theory

Function:

Used to characterize the particle size and distribution of emulsions, county floats, and powders.

-

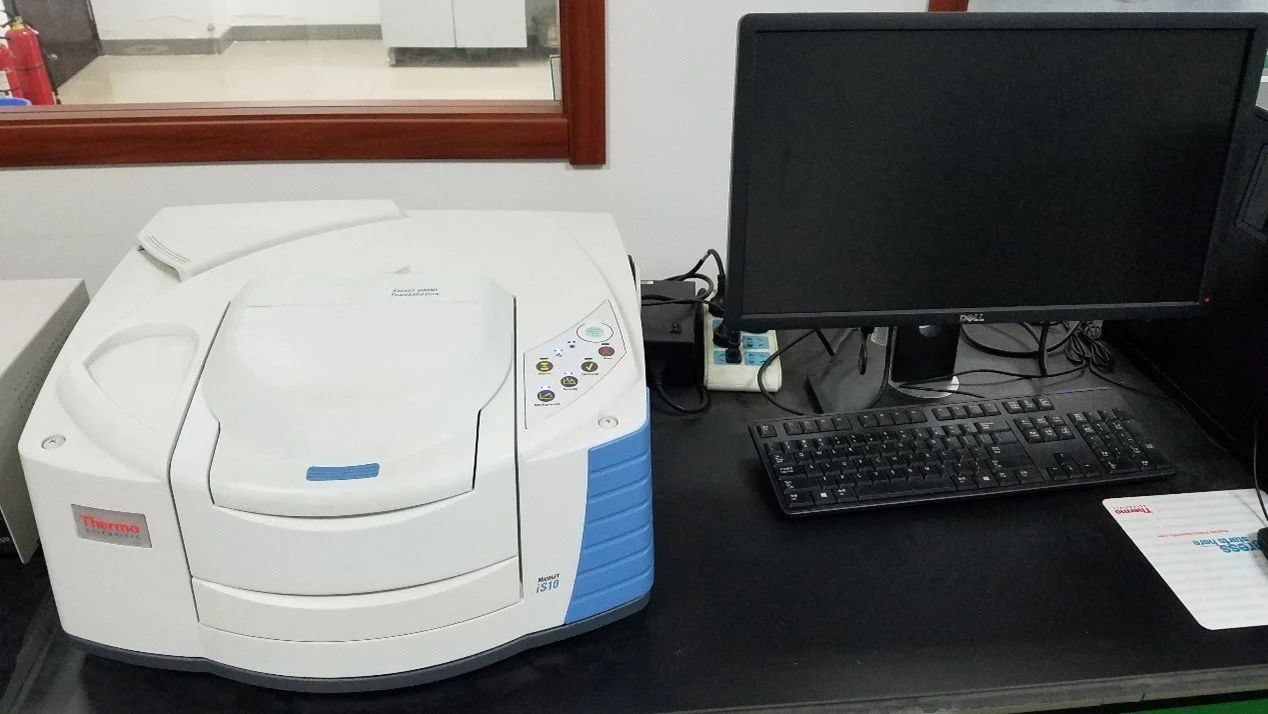

FT-IR Spectrometer

Index:

Digital interferometer, dynamically adjusted up to 130000 times per second;

Signal-to-noise ratio (peak to peak, 1 minute scan): Up to 50000: 1

Spectral range: 27000-15 cm-1

Resolution: 0.09cm-1, 0.4cm-1

Function:

Used to analyze the molecular structure of polymer materials such as resins and sizing agents, as well as the structure of inorganic silicate materials.

-

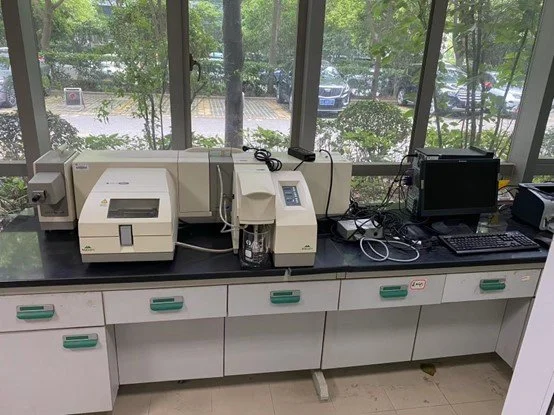

Differential scanning calorimetry

Index:

Temperature range: -170 ° C~600 ° C.

Heating rate: 0.001K/min~100K/min

Cooling rate: 0.001K/min~100K/min

Measurement range: 0mW~600mW

Function:

Determine the melting and crystallization process, crystallinity, glass transition, phase transition, liquid crystal transition, oxidation stability (oxidation induction period O.IT), reaction temperature and reaction hot melt of materials, and determine the specific heat of substances

-

High temperature viscometer

Index:

Temperature range:RT-1600℃;

Viscosity measuring range:1000cp-5×106cp

Function:

It can be used to test the viscosity and temperature curve of molten state of glass, ceramic, slag, protective slag, coal ash, etc. The volume change caused by homogeneous polycrystalline phenomenon; Contraction or expansion of fibers or films, etc.

-

Thermal mechanical analyzer

Index:

Temperature range: -150~1550 ° C

Maximum measurement length: 30 mm

Measurement range: 2.5 mm

Displacement resolution: 0.125 nm

Load capacity: 0.001N-±3N (in steps of 0.2 mN)

Resolution of force: 0.01 mN

Function

The thermal expansion coefficient CTE, viscosity, and stress-strain relationship of the material; Glass transition and softening temperature; Stability of materials during heating, viscoelastic behavior, and volume branching caused by homogeneous polycrystals; Shrinkage or expansion of fibers or films.

-

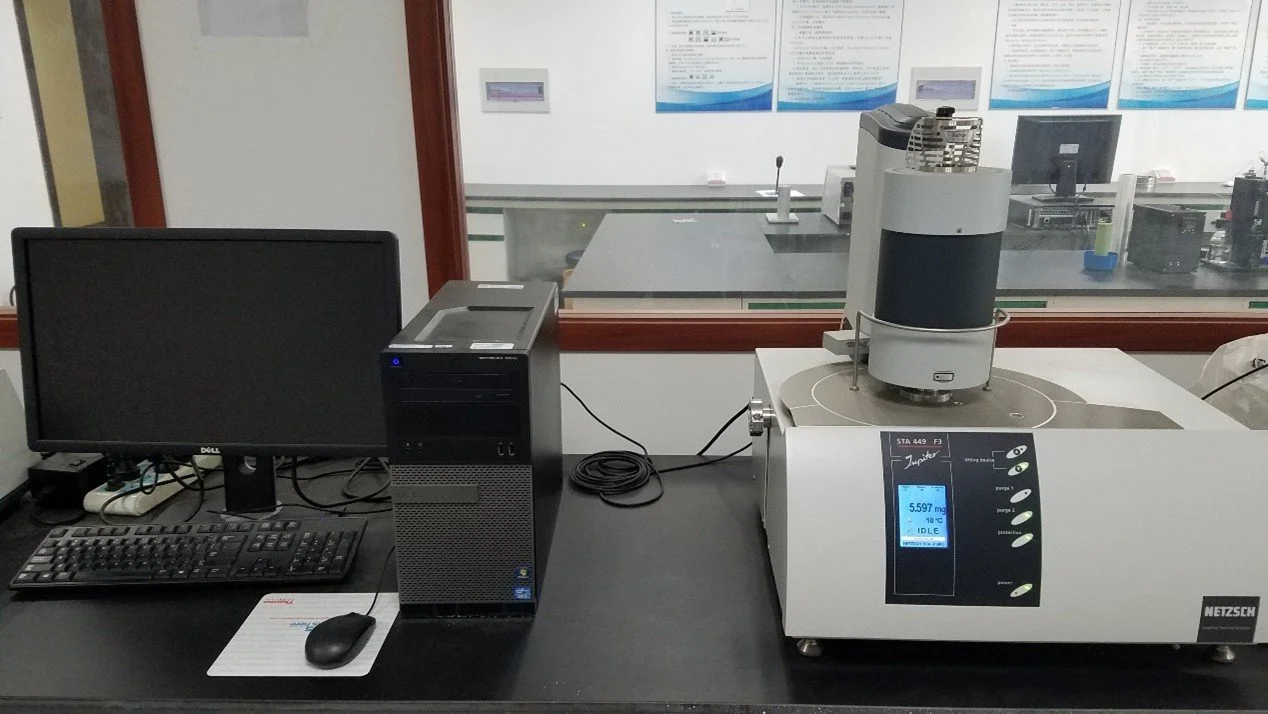

Simultaneous thermal analyzer

Index:

Temperature range: RT~1500℃;

Rate of temperature fall: 0.001K/min~50K/min;

Weighing range: 35000mg;

TG resolution ratio: 1μg;

DSC accuracy: <1μW

Rate of temperature rise: 0.001K/min~50K/min;

Function:

Simultaneous testing of the thermal effect (transition temperature, enthalpy) and mass changes of the sample, rapid and in-depth characterization of the material's thermal stability, decomposition behavior, component analysis, phase transformation, melting process, etc.

-

Thermal constant analyzer

Index:

Thermal conductivity range:0.005—500 W/mK

Temperature range:10 K—1000 K

Joint dimension: 2-29.40 mm

Accuracy: ± 3%

Function:

It can be used for the determination of solid, powder, coating, film, liquid, anisotropic material and other thermal property parameters. The direct measurement of transient heat propagation with a test time between minutes and seconds can save a lot of time

-

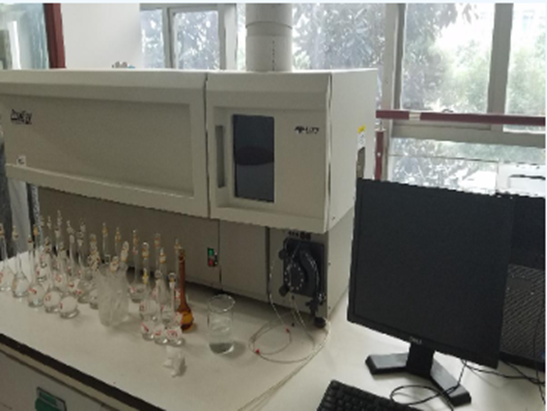

Full spectrum direct reading ICP emission spectrometer

Index:

wavelength coverage: 165-1100nm;In special cases, 120-165nm configuration can be selected to facilitate the analysis of ppb halogen elements;

resolution ratio: 0.005nm (200nm);

accuracy: RSD% < 0.5%(n=10);

stability: RSD% < 1.0%(8 hours)

Function:

Qualitative and quantitative analysis of materials, quantitative analysis of various elements above ppb level in basalt ore

-

High temperature physical properties analyzer

Index:

Contact Angle measurement range: 0~180°, measurement accuracy: ±0.1°

Surface tension measurement range: 0~2000mN/m;

Measurement accuracy: ±0.5mN/m

Temperature accuracy: 1℃;

Maximum test temperature: 1800℃;

Rate of temperature increase: 20-30℃/Min.

Function:

The main measurement of glass, ceramics, welding materials, refractories sintering, softening, melting, fluidity and wettability and other high temperature physical properties, quantitative measurement of high temperature melt softening point, hemisphere temperature, sphere temperature, flow temperature, easy to set the corresponding basalt fiber production wire drawing process parameters. The high temperature physical property parameters of various samples were obtained.

-

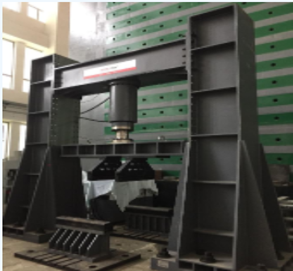

High temperature creep testing system

Index:

Test force measurement range: 1% -100% FS

Test force accuracy: 0.5%

Test force resolution: 1/300000 of the maximum test force (full range resolution remains unchanged)

Maximum loading rate: 3000N/s

Loading accuracy: indication error+0.5%

Functions:

The system is used for testing the mechanical properties of materials. In addition to conventional creep and endurance tests, it can also perform stress relaxation tests, high-temperature short-term tensile tests, low cycle tests, and other tests.

-

Digital Material Testing Control System

Index:

Test force measurement range: 500 kN

Function:

Fatigue and static tests

-

Servohydraulic Fatigue Testing Machine

Index:

Power supply conditions: Voltage: 220V/380V+10%, single-phase and three-phase

Frequency: 50Hz+2HZ.

Environmental conditions: temperature conditions of 10~35 ° C, humidity conditions of 10%~80%.

Working hours: The equipment can work continuously for a long time

Main technical specifications and parameters of the equipment

Axial/torsional load capacity:+/-25kN/+-100Nm

Load measurement accuracy:+/-0.005% of full range, or+/-0.5% of indicated value (within the range of 1% to 100%)

Position measurement accuracy: 0.5% of full range

Stroke of the actuator:+/-50mm.

Torque range of the actuator:+/-130 degrees

-Dynamic response adaptive control system. Continuously updating PID parameters at a frequency of 1KH, without the need for users to set parameters during PID adjustment, can automatically compensate for sample stiffness.

-5KHz closed-loop control rate.

-6 parameter control: proportional, integral, differential (PID), serial, parallel, and cascade control.

Function:

Fatigue tests of FRP, composites reinforced with steel and fiber.

-

SEM high temperature fatigue testing machine

Index:

Test load: ±10KN

Maximum displacement:±10mm

Function:

It is used to observe the microscopic damage of the sample surface dynamically during fatigue test. It can carry out pull-pull, pull-pressure, three-point bending fatigue test and high temperature test below 800℃. Special point: The electron microscope SEM and testing machine adopt the integrated structure, with high anti-vibration effect. Observation test of crack growth can be carried out at the same time with SEM observation.

-

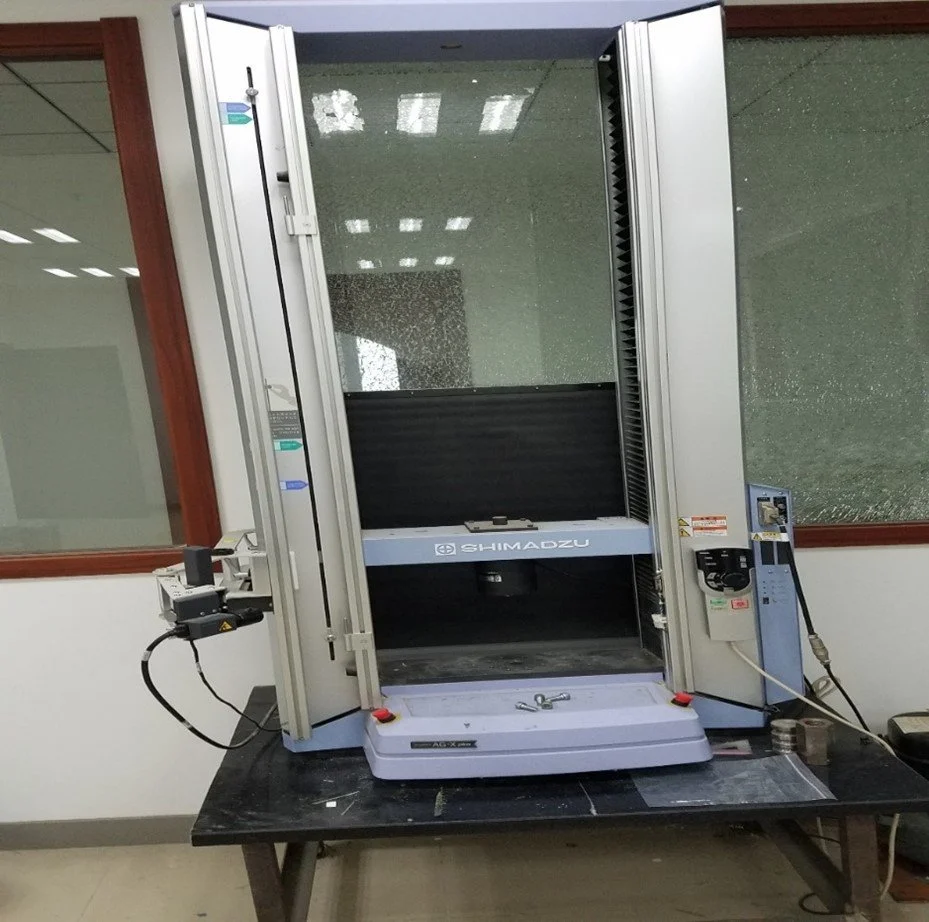

Universal testing machine

Index:

Capacity 10kN ; 0.5 class

Force measurement accuracy:1/1~1/100

Load sensor capacity 10N Level 1

Pull/press two-way

Function:

Used for tensile and compressive testing of structural specimens to test their mechanical properties.

-

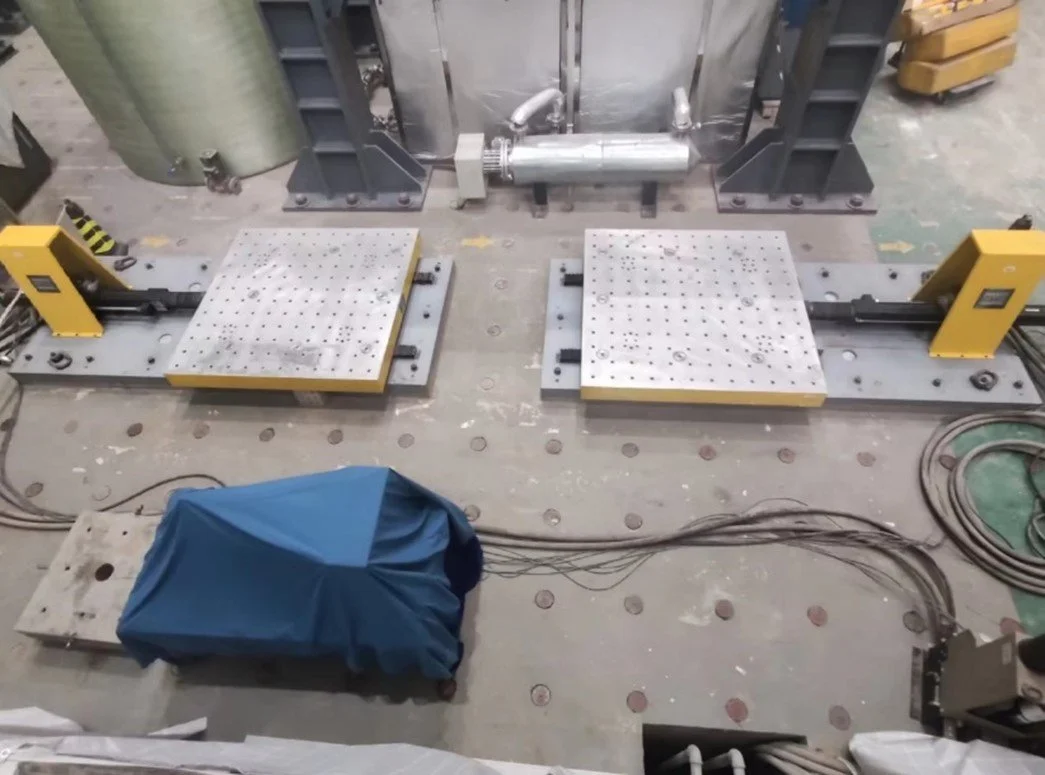

Single axis seismic simulation vibration table system

Index:

Table size: 1.5 meters *1.5 meters

The countertop includes M16-2 mounting holes

The countertop is made of silver alloy material; Table weight 925KG;

The maximum load-bearing mass of the test piece is 2 tons;

Maximum overturning moment: 10 meter ton

Frequency range: 0.1-50 Hz

Dynamic displacement: 400 mm total

Maximum speed: 1.0 mm/S

Maximum acceleration with rated maximum specimen mass: 1.1g

Maximum no-load acceleration: 2g

20 hole locations, 30mm diameter per hole location

Assembly without test piece mass 5300 Kg

Function:

The single axis seismic simulation vibration table testing system is mainly used for mechanical and damage tests and analysis of civil engineering, transportation structures, and components under simulated vibration waves (such as seismic waves). It is used for seismic analysis and research of structures, as well as for dynamic testing of sensors, and can achieve array testing functions.

-

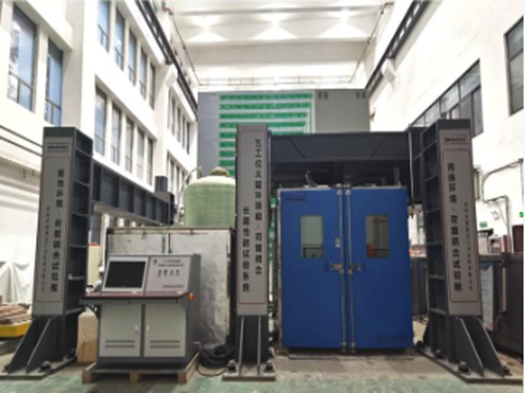

Large environmental simulation cabin-creep load long-term performance testing system

Index:

The largest test load: ± 500kN;

Station: 5 stations

Piston stroke 300 (± 150) mm

Accuracy level 0.02 maximum lateral load ± 100% (static)

Maximum lateral force 100%

Safety overload 150%

No damage, safety overload 300%

Temperature range: -30 ℃~350 ℃;

UV wavelength range: 295 nm~400 nm

Function:

Mainly used for dynamic and static mechanical performance testing of various concrete beam and column structural components, including three-point bending, four-point bending, compression, creep, and other products. Equipped with a large environmental simulation cabin, it can complete environmental simulation tests in high temperature, acid, alkali, salt corrosion, and ultraviolet environments.

-

3000kN microcomputer controlled electro-hydraulic servo pressure testing machine

Index:

Maximum pressure load: 3000kN, maximum clearance: 330mm

Function:

Compressive strength test of concrete specimens and concrete structural components, and compressive strength test of metal materials and metal structural components.

-

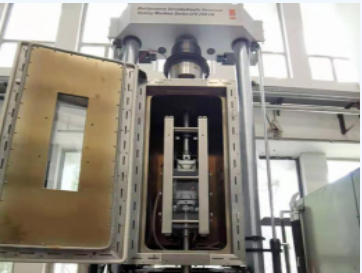

2000kN microcomputer controlled electro-hydraulic servo universal testing machine (frame)

Index:

Maximum pressure load: 2000kN,

Maximum tension load: 1000kN;

Effective test space less than 1800mm

Function:

Cooperating with reaction walls and reaction foundations, it can be expanded into a multi-directional loading system for conducting tests on large-span beams, compression tests on large column components, and tests on long column nodes

-

Microcomputer controlled electro-hydraulic servo universal testing machine

Index:

The maximum load:2000kN, maximum clearance: 1500mm

Function:

Tensile and compressive performance testing, elastic modulus testing for metal and non-metal

-

Hydraulic servo testing system

Index:

Technical parameters

Maximum dynamic load force ± 250kN; Accuracy level 0.5; Maximum static load force ± 300kN; Piston stroke 150 (±) 75mm

High temperature resistant hydraulic fixture

Plate clamp 0-10mm × 60mm clamp block

Bar clamp φ 4.5-11.5/13.5mm clamp block

Mechanical fixtures for acid alkali salt corrosion resistant fatigue machines

Plate fixture 0-10mm × 60mm clamp block

Bar clamp φ 4.5-11.5/13.5mm clamp block

High and low temperature resistance (-40-+100 ℃), acid alkali salt corrosion axial extension meter, and equipped with gauge adapter

environmental boxes

Temperature range: room temperature~+350 ℃

Minimum temperature -120 ℃

Heating time to maximum temperature<70 minutes

Heating time to minimum temperature<90 minutes

Temperature stability ± 2 ℃ (at 350 ℃)

Power supply 230V, 50HZ, 6KW, 32A

Corrosion box

Temperature range: room temperature~+90 ℃

Salt spray corrosion component pump, liquid distribution device, spray device

Solution type: acid, alkali, salt solution

Function:

It can be paired with various different environmental testing systems (high temperature, low temperature, salt spray, acidic, alkaline environment, etc.) to achieve coupling fatigue performance testing of components under different corrosion/high and low temperature environments. The hydraulic fixtures, corrosion chambers, immersion extensometers and other accessories of the system must be resistant to high temperature corrosion.

Some of our Facilities at the University of Leeds

Will be updated shortley.